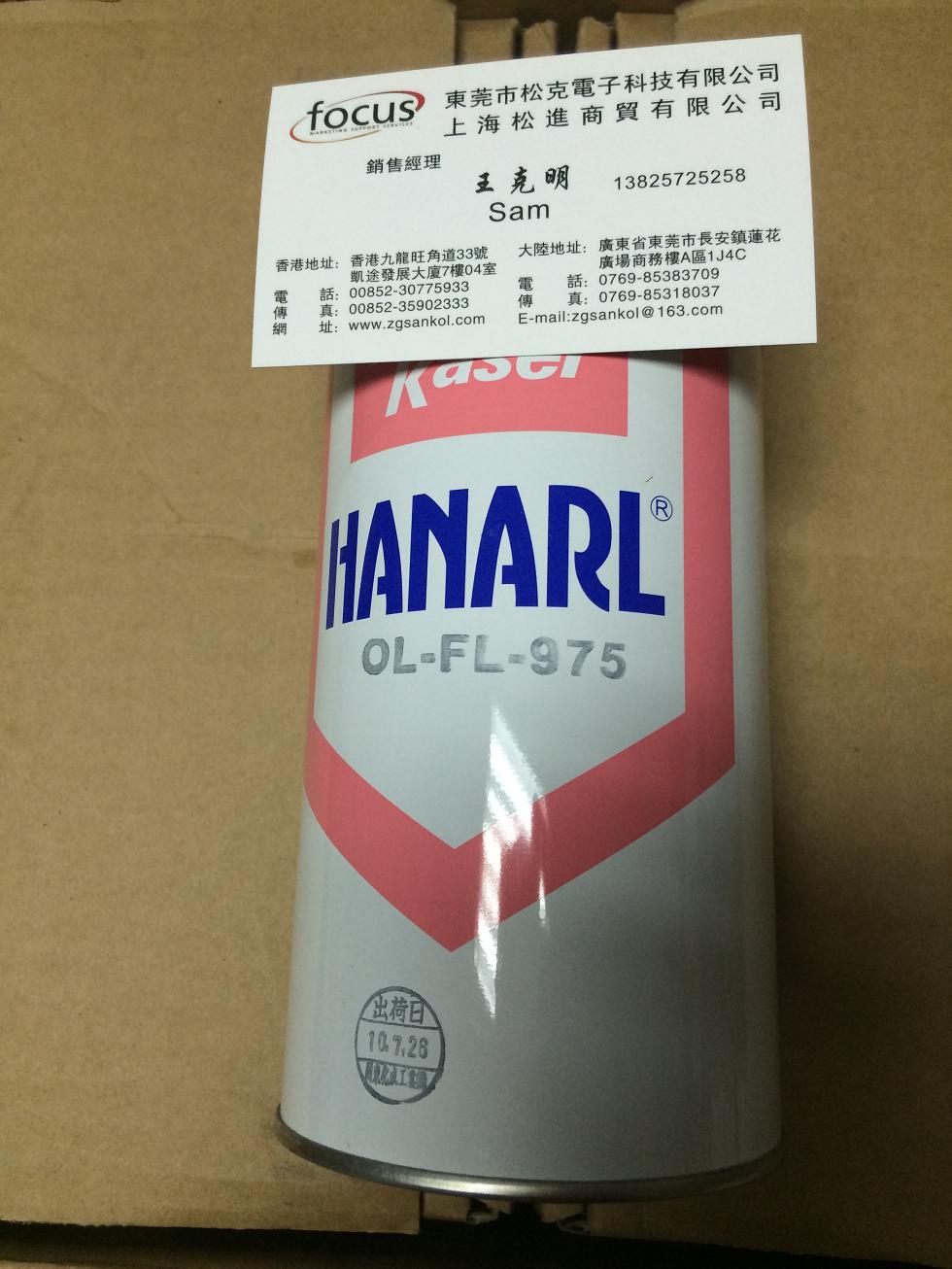

Fujitsu red plastic patch

SMT red plastic (agent Fujitsu Series)

Long-term sales of original authentic Fujitsu red plastic NE3000S NE8800T NE8800K

200G / support and dedicated high-speed dispensing with red plastic small 40G

SMT patch red plastic

First, the characteristics:

1) allows low temperature curing;

2) The small amount of high-speed coating and printing, without drawing, tailing and pollution;

3) a variety of surface mount components, and then given strength can be obtained;

4) excellent storage stability;

5) Good heat resistance and excellent electrical properties;

II. Characteristic parameters:

Property name NE8800T NE8800T NE3000S the appearance of red epoxy resin component epoxy paste red paste the proportion of red paste viscosity 1.28 1.38 1.38 (25 ℃ 5rpm) 300,000 cps 450,000 cps 390,000 cps Thixotropic Index 6.8 (1rpm/10rpm ) 6.8 (1rpm/10rpm) 5.0 (1rpm/10rpm) use dispensing and printing characteristics, low viscosity, dispensing and printing, special printing high viscosity adhesive strength 1. 44N (4.5kgf) 0.2mg two-point (2125C) 2. 45N (4.6kgf) 0.3mg double points (small transistor) 3. 92N (9.4kgf) 0.8mg double points (SOP IC 16P) volume resistance 2.6? 1016Ω? cm JIS K6911 insulation resistance of 2.6? 1016Ω? cm JIS K6911 early start value of 1.0? 1014Ω JIS Z2317 after 1.2? 1012Ω 3.62/1MHZ JIS K6911 dielectric constant of dielectric loss angle 0.013/1MHZ JIS K6911 preservation conditions in the 5? 3 ℃ in the refrigerator

III. Curing conditions

1) The proposed cure is when the surface of the substrate after the temperature reaches 150 ℃ to 120 ℃ 60 seconds or 90 seconds;

2) the higher the curing temperature and longer curing time, bonding strength is stronger.

3) The temperature of the plastic substrate with the size and placement location of components vary, we recommend to identify the most suitable curing conditions.

IV. Use

1) To maintain the quality of adhesive patch, please put in the refrigerator cold (5? 3 ℃) storage;

2) Remove from the refrigerator before use, the next time temperature should be at room temperature for 2 to 3 hours;

3) at the point in Jiaruhousai hose, you can get a more stable point of glue.

4) The recommended dispensing temperature 30-35 ℃.

5), decorated hose, use a special glue of the Company to sub-sub-installed equipment to prevent air bubbles in the glue in the mix;

6) toluene or ethyl acetate can be used to clean the hose.

7) The uncured adhesive can be toluene or isopropanol wash from the PBC board.