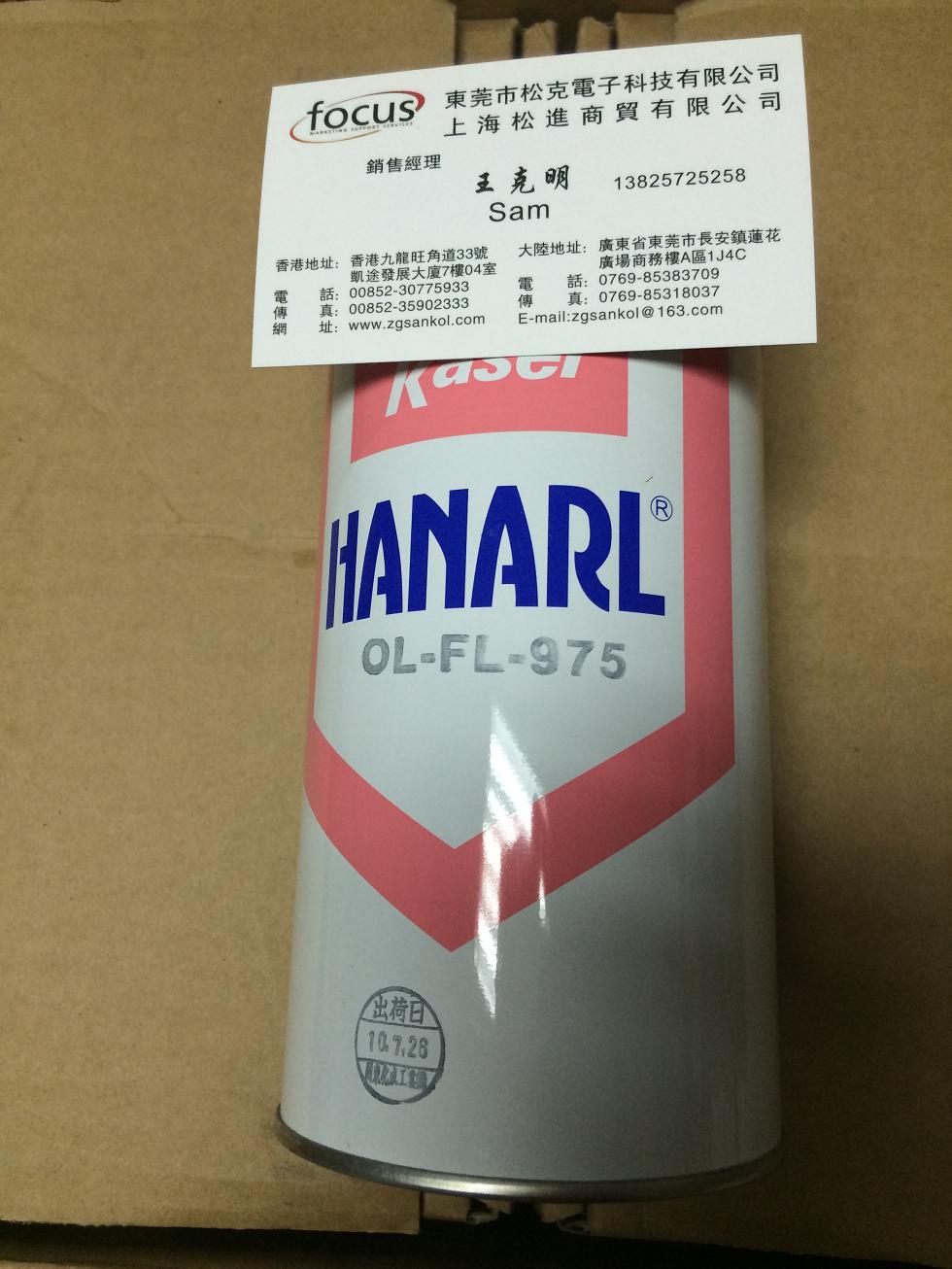

Aluminum Wear Compound

Description: Blended aluminum-filled epoxy putty, used to repair fatigued metal surfaces where exceptional durability and ruggedness

is required.

Intended Use: Product designed to repair leading edges of molds that have worn because of abrasion or constant use. Material can

adhere to all metal surfaces and withstand wear and abrasiion in a constant demolding application.

Product Fills voids or pores in castings

features: Protects metal from bi-metallic corrosion

No-shrink curing

Application Spread mixed material to repair area and work firmly into substrate to ensure maximum surface contact. Aluminium Wear

Instructions: Compound fully cures in 24 hours, at which time it can be machined, drilled, or painted.

FOR BRIDGING LARGE GAPS OR HOLES

Place fiberglass sheet, expanded metal, or mechanical fasteners between repair area and Aluminium Wear Compound

prior to application.

FOR VERTICAL SURFACE APPLICATIONS

Aluminium Wear Compound can be troweled up to 3/4" thick without sagging.

FOR MAXIMUM PHYSICAL PROPERTIES

Cure at room temperature for 12-16 hours, then heat cure for 2 hours at 150°F.

FOR 70°F APPLICATIONS

Applying epoxy at temperatures below 70°F lengthens functional cure and pot life times. Conversely, applying above 70°F

shortens functional cure and pot life.

CURING INSTRUCTIONS

Aluminium Wear Compound will cure in a thick section, [ >1/2" thick] at 75°F in 4 hours. The material will be fully cured in

16 hours for full chemical immersion.